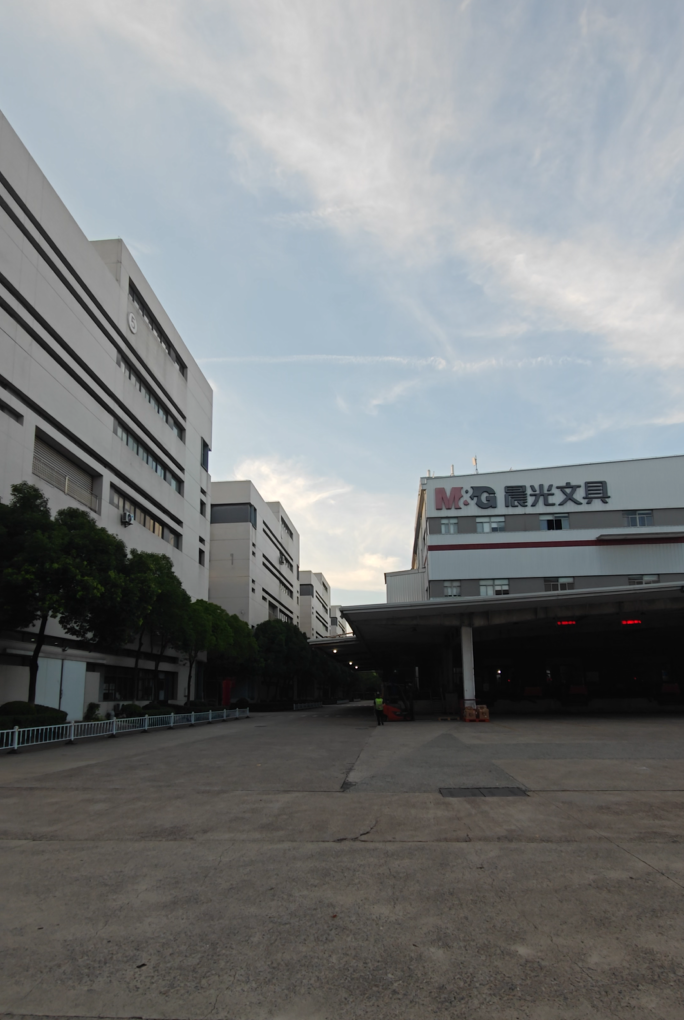

Application of Yuanjie Dry Ice Blasting Machine YJ-06 in the Injection Molding Workshop of Shanghai M&G Stationery INC Headquarters

M&G Stationery, as one of the world’s largest stationery manufacturers, is an integrated supplier combining creative value with service advantages, committed to making learning and work more enjoyable and efficient. Its product portfolio encompasses writing instruments, student supplies, office supplies, and related products. The company was listed on the Shanghai Stock Exchange in 2015 under stock code 603899.

The headquarters is located in Shanghai, China, housing the M&G Stationery Industrial Park spanning 650 acres. This site hosts:

China Writing Instrument Industry Base

China Writing Instrument Center

National Industrial Design Center

Key Laboratory of Light Industry Writing Instrument Engineering Technology810

The facility produces 15 million gel pens daily, with annual output reaching 5 billion units, solidifying its position as China’s stationery industry leader.

At its Shanghai headquarters, M&G operates over 1,000 injection molding machines across 5 factories. To enhance product appearance and dimensional accuracy, the company has prioritized a Dry Ice Blasting maintenance initiative, implementing Yuanjie YJ-06 Dry Ice Blasting machines for mold cleaning and maintenance in all injection molding workshops.

Yuanjie YJ-06 Dry Ice Blasting Comprehensive Benefits in M&G’s Mold Maintenance

Core Technical Advantages

Non-destructive Cleaning:

Utilizes dry ice pellets (-78.5°C) to embrittle contaminants, paired with high-pressure airflow (0.4-0.6MPa) for non-contact removal. This prevents chemical corrosion or mechanical damage to mold surfaces, ensuring dimensional stability of high-precision molds.

Cleaning Efficiency: Single mold cleaning time averages 20 minutes, reducing duration by >80% versus traditional methods.

Environmental Compliance:

Dry ice sublimates into CO₂ only, eliminating wastewater, chemical residues, or secondary pollution, fully compliant with ISO 14001 standards.

Performance Enhancement Analysis

Product Quality: Removes carbon deposits, oil residues, etc., reducing burrs and surface defects on molded parts. Final product qualification rate increases by 4%-15%.

Production Efficiency: Supports online cleaning (operable at mold temperatures ≥80°C), minimizing disassembly and downtime. Overall production line efficiency improves by ~300%.

Cost Optimization: Extends mold lifespan by >25%, reduces maintenance costs by 30%, and saves chemical solvents/water resources.

Application Adaptability

The YJ-06 employs a “Embrittlement-Microexplosion-Airflow Transport” triple-action mechanism, delivering efficient, precise, and sustainable mold maintenance. Using 3mm dry ice pellets (actual particle size upon blasting: 0.2-1.5mm), it suits complex molds including injection, die-casting, and PMMA/PET/POM molds, excelling in cleaning deep holes and narrow slots inaccessible by conventional methods.